Complicated planning and scheduling

The traditional scheduling mode can no longer adapt to the great fluctuations of customer requirements, short delivery cycle and long manufacturing cycle. Automation improves the changeover efficiency.

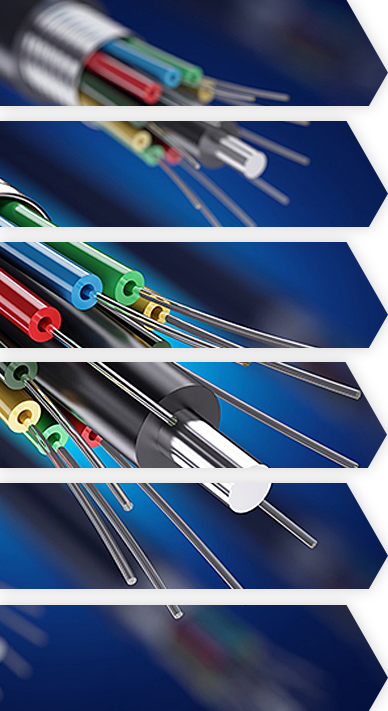

Complicated manufacturing processes and difficult error proof and traceability

"Wires and cables" is the high asset investment industry with diversified raw material mix, complex production processes, a low degree of automation, excessive reliance on personnel and equipment in the production process, and high requirements on error-prrof and traceability.

Equipment and tooling management

"Wires and cables" involve complicated production processes and a large amount of manufacturing and processing equipment. The difficulty in equipment and tooling management brings about difficulty in preventive maintenance, failure in process anomaly control, low utilization rate of equipment and high maintenance cost.

High inventory of WIP

Long manufacturing cycle, frequent changes, long changing verification process , difficult to control, too many breakpoints in the process, high inventory of WIP, extensive use and waste of capital.

MES(Manufacturing Execution System)

Realize the production management of wire cutting, stranding, welding and semi-automatic crimping areas; optimize process management; achieve final assembly—test—packaging management; support order-based production, pull production, KSK production mode, automatic scheduling, real-time receipt of production performance.

EAM(Enterprise Asset Management System)

Realize the life cycle management of equipment, fixtures and spare parts based on EAM; monitor the tooling usage times and establish a scientific TPM system; SMED production switchover warning; reduce the mold purchase cost by about 10%.

KSK

Achive data message analysis, data verification, order sorting, from the source of error-proof and abnormal reminder. Realize the wire harness production from the traditional material number production mode to modular customized production, and combined with MES to realize the production process error-proof, optimize the order settlement method of finished products, to meet the needs of high-end customers.

Cost reduction

Reduce the inventory of WIP by about 30% and material slow-moving cost by about 30%; provide a transparent, modernized and intelligent manufacturing process.

Paperless management

Realize electronic kanban release management and electronic pull, reduce the paper change cost caused by engineering changes; provide electronic and intelligent process management, reduce paper operation guidance, and offer efficient production guidance.

Efficiency improvement

Improve the OEE of pre-process automaton equipment by about 10%; provide early warning, change from passive to active, establish a rapid response system, reduce the line shutdown cost due to lack of materials and equipment anomalies.

Quality improvement

Achieve whole-process 6M traceability; effectively realize the process, material and manufacturing process fool-proofing and error-proof management, reduce production anomalies, improve yield, decrease customer complaints; pass the audit of Mercedes, BMW, Volkswagen, Volvo, Tesla and other high-end customers.

Shortened delivery cycle

Shortened manufacturing cycle: shorten the change and verification cycle by about 50%.

Quick response

Establish a rapid response system to reduce the line shutdown cost due to lack of materials and equipment anomalies; establish a scientific EAM system to improve the quality and efficiency of tooling and fixture maintenance.

WMS

Warehouse Management System

MES

Manufacturing Execution System

Sichuan Yonggui Technology Co., Ltd

Mianyang,Sichuan

Aptiv Centers Electric (Shanghai) Co., Ltd

Shanghai

Hebi Tianhai Global Electric Appliance Co., Ltd.

Hebi, Henan